2026 - Year of the Hoe

Forward

About a year ago, I wrote a lengthy post about all of the maintenance and repairs I had done on my 2008 Chevy Tahoe, which I named “Casper.” Casper is a cursed truck, and I’ve been painstakingly exorcising the evil spirits. It’s clear my wife hates this vehicle, and isn’t fond of the moniker. I had originally intended my blog to be a space to write about Computer Science and Technology. Instead, here’s another article about Automotive Engineering. Here’s a rundown of the repairs and upgrades I did this season:

Onboard air system:

Okay, I actually did this upgrade over the summer, and my Dad helped a fair bit, but it’s still awesome. I added a VIAIR light-duty air system. It’s a little 1 gallon compressed air tank with a light-duty compressor assembly. It runs off the vehicle’s 12 volt battery. It sits in the driver’s side battery tray, which was empty on my Tahoe. I also fixed a small issue with finding a good electrical ground about a month ago.

With the compressor, I can bring an auxiliary 6 gallon tank under 105 PSI, which enables me to run most pneumatic tools

I used it recently to try and rip some high-torque bolts off a tractor, but unfortunately my impact gun’s rating is too low, so we’ll circle back around on the tractor later this spring.

I haven’t found an ideal use case for this upgrade otherwise. It can technically be used to run air bags, air-locking differentials, or pump tires. The intended use case was to service the tractor, but I might just attach a train horn to it instead, because I can. Choo choo.

Fuel Pump Control Module

Around October I got a “Check Engine” light (surprise.) This was shortly after I did a Texas-to-Chicago run to visit my dad, which always seems to break something on my vehicle. I had replaced the Engine Temperature Sensor a few weeks prior, so my assumption was the cooling system was acting up again. I threw some coolant in it and had the guys at Autozone clear the code, but it came back a couple days later.

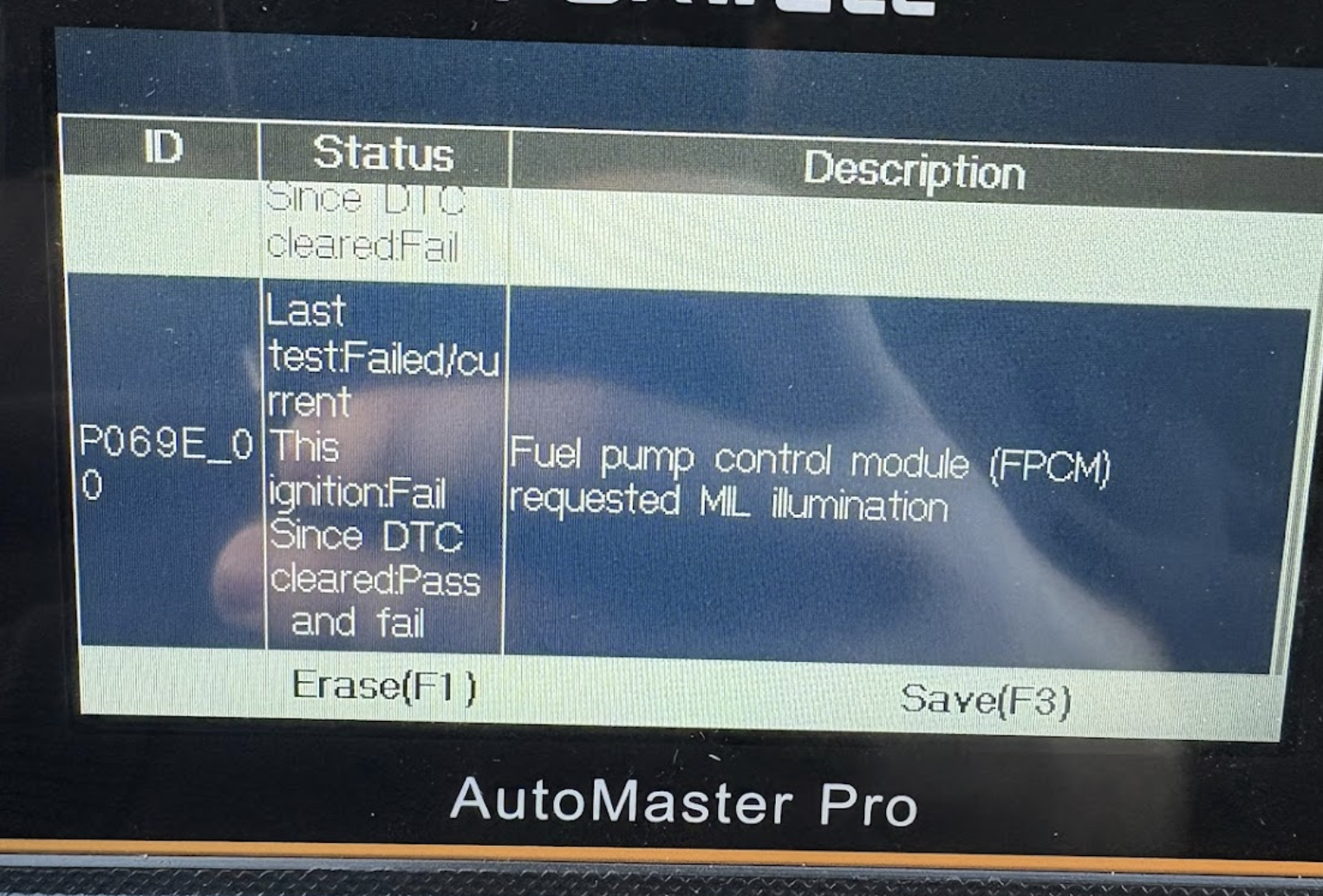

It wasn’t until I returned to Texas that I could pull the code, which was P069E_00.

This code can mean a few things: Fuel rail pressure can be low, the fuel pump might be failing, the fuel system might not be air-tight. I probably should have pulled the live fuel rail pressure feed as a diagnostic test. I think my scanner can do that, but I just YOLO’d in a new Fuel Pump Control Module instead.

A few interesting notes here: Dorman brand modules don’t require programming. This one I got on Amazon.

Also, nearly all the videos on Youtube describe the location of the module as being under the spare tire in the rear of the vehicle. My spare tire was rusted onto the frame and I spent about an hour hammering and prying to finally free my tire. I’m glad I did this in the garage, and not on the side of the road when I actually needed it, because I would have been in trouble.

I was fully bewildered to find there was no FPCM in the described location from YouTube. It took about an hour of research and poking around the undercarriage to locate and replace the FPCM (which I did a shitty job of, because GM makes it impossible to swap the module without dropping the fuel tank.)

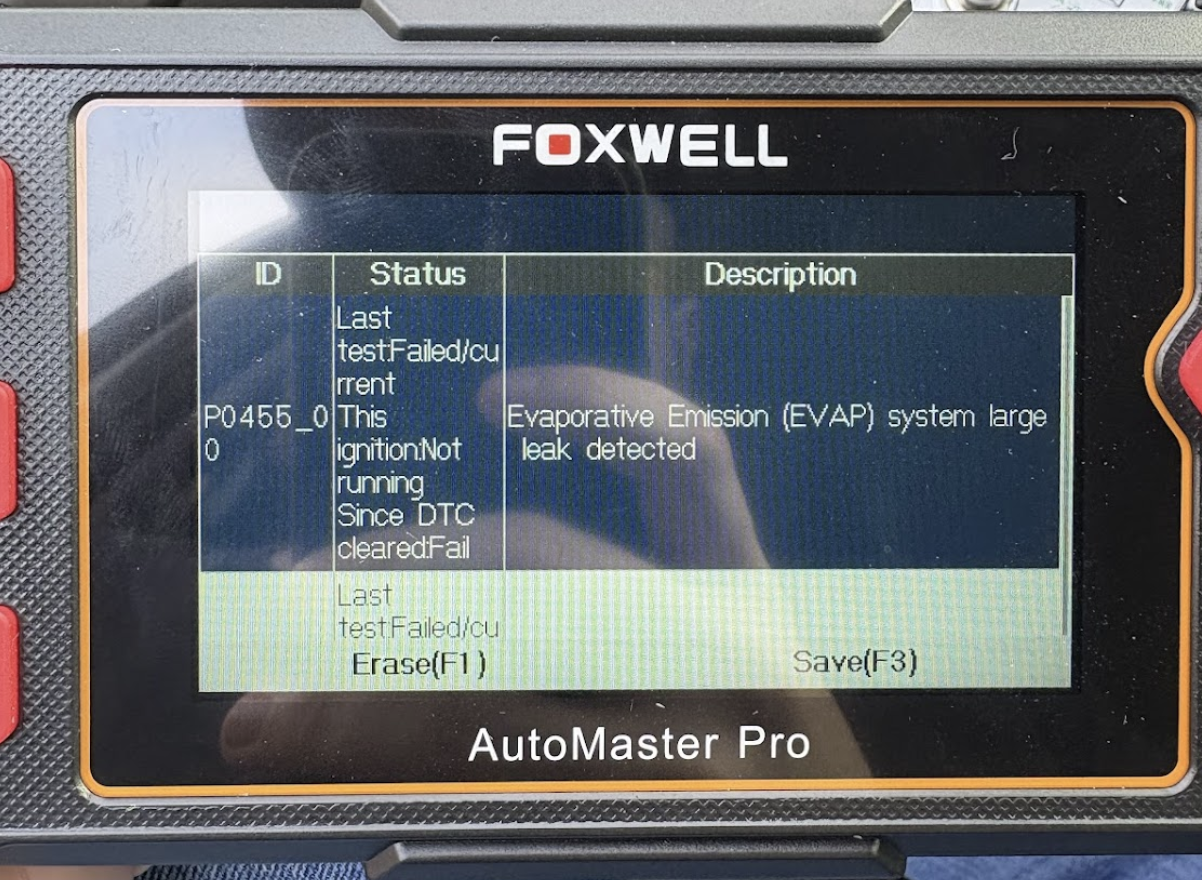

The fuel system has been a little less temperamental since I replaced the module. I did get an EVAP system code once or twice since I replaced the FPCM (P0455_00).

I am not positive on the implications of the EVAP system code, but I’m pretty sure it’s a non-issue, and points to a failing fuel pump or that my fuel system isn’t air-tight.

At any rate, I’m done dealing with GM’s fuel system bullshit for a while.

Debadging and tire detail

This is a simple cosmetic upgrade. My Tahoe had a couple dealership stickers and OEM badges. They’re visible here (don’t steal my license plate and be a jerk)

I don’t mind the chrome badges, but the “FlexFuel” badge is ugly.

The wheels also look like they’ve never been detailed ever. There was about an eighth of an inch of grease and mud in the wheel well.

So I took a heat gun and eraser wheel to the badges and decals, and used a drill detail brush to clean up the wheels. I finished up with a basic maintenance car wash at the local automatic car wash, and the results were fantastic:

The wheels are shiny, and there’s no sign of garbage dealership or OEM decals. We can think about chrome door trim and chrome running boards, but I feel like I still have mechanical work I need to prioritize before we start getting deep into cosmetic stuff. The debadge and detail project was cheap and easy. I don’t want the Hoe to look like a gold-painted turd, so we’ll continue mechanical work through the summer.

Hidden Winch and Dedicated Transmission Cooler

This was the big project for the Holidays. I bought a 12,000lb Badland Apex winch about a year ago. It’s been sitting in a box in the corner of my garage since we moved to Texas. I also bought a Rough Counry winch mount.

Why put a 12,000 lb winch on a Chevy Tahoe? Well, it’s 4WD, it’s got offroad tires, and I actually offroad with it when I’m at my Father-in-law’s farm. I’ve also been into Matt’s Offroad Recovery a lot on YouTube, and like watching him do crazy stuff with these machines. They’re useful for moving heavy equipment, and pulling cars out of snow drifts, which isn’t necessary in Texas, but I’m in Illinois often enough in the winter time, that I don’t hate the idea of having one.

So, that became the mission this Holiday season. I based the project heavily on the installation procedure described in this YouTube video. Pretty much, you remove the whole front end, grind down some bumper brackets, drill holes, add some Grade 8 bolts, do some light fabrication on the winch mount, and cut a hole in the front bumper. This was probably the biggest automotive project I’ve done since I took Automotive in high-school. Here are some photos:

You may notice the new transmission cooler in the above photos. That’s an in-progress installation based on this YouTube video. It’s physically installed, and the coolant lines are routed to the proper location, but not connected. The reason for this is because I need to do a transmission fluid drain-and-fill before I can connect these lines, which will be something I do in Spring. Basically, my transmission temp gets too high when I’m towing close to my 7000lb capacity. The YouTuber above mentioned this upgrade reduced their operating temperature by about 20-30 degrees for their transmission when it’s under load.

The biggest challenge with this project was actually related to body-work. It looks like someone has been into the front-passenger quarter panel and all of the mounting brackets are bent and messed up. It took hours to get the front-end back on after I got the winch mechanically mounted.

Here’s the finished product

Badland Apex Winch mounted with Rough Country hardware!

I did test the winch recently also. I was able to pull a 4 ton tractor without blinking, which seems like an important detail.

Anyways, I’ve got some misc. things planned for 2026, but that’s all for now !